One of the main factors when it comes to the construction of any machine is its durability. Without this element, even the best machines in the world do not mean a lot because they simply will not last. With a high level of durability, on the other hand, a machine can continue to accomplish its purpose over a prolonged period of time, providing its users and operators with all of its benefits. The same notion is true for any machine in the world, including trucks. As vehicles that are often the beast of labor for their owners, trucks are not the type of vehicle which receives a gentle treatment. If you own a truck, this idea is most likely well known to you, primarily from experience.

Instead, a lot of trucks operate in really harsh environments, where things like moisture, dirt, and prolonged periods of intensive workload generate a lot of strain on their engines. Because of this fact, having a durable engine is probably the most important thing about any truck out there, past or future. But, while many people believe that engine’s durability is simply provided by the factory that made it, the truth is that even small advancements in engine’s construction can mean a lot when it comes to its working life. Fuel solenoid shut off valves are probably one of the essential devices which can change the outlook for any truck’s engine lifespan and its general durability levels. Here are the reasons why these simple additions can really produce great results when it comes to standardizing your truck’s durability.

How does the Fuel Solenoid Shut off Valve Work?

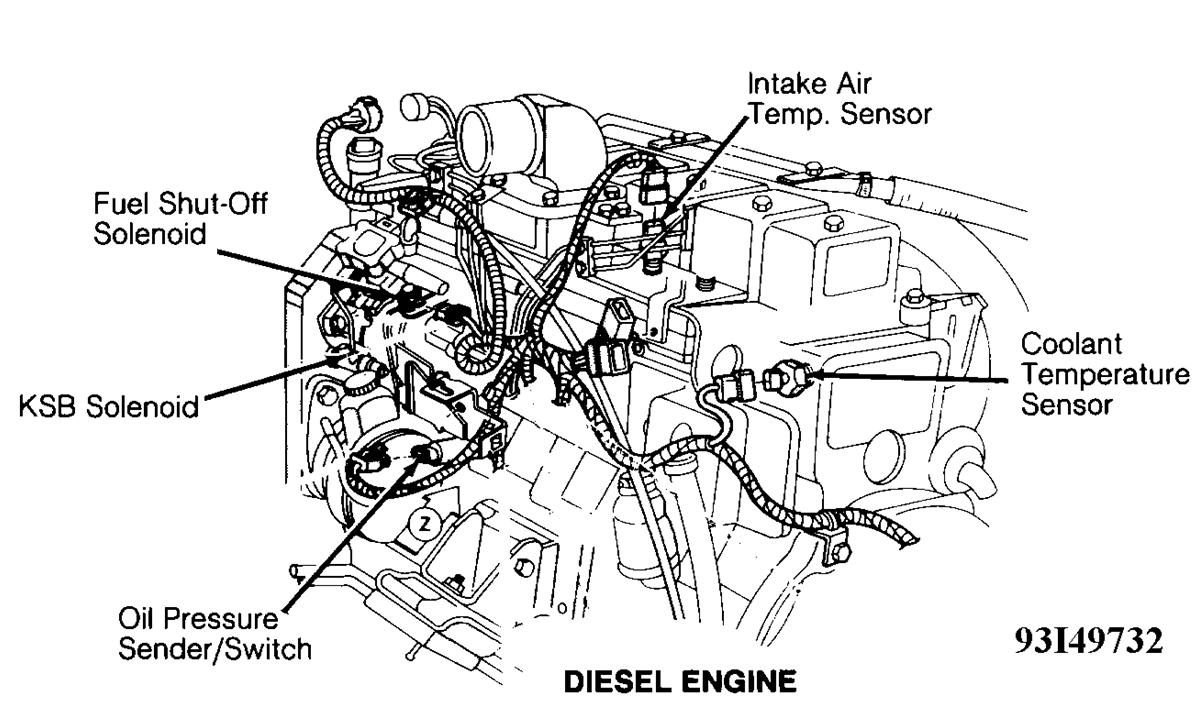

The purpose of these devices, to put it in the most basic term, is to add a lot more control in the process of fuel consumption that takes place in an engine of a vehicle while it is not operational. Fuel solenoid shut off valves are used to close the primary jet of fuel coming into the carburetor at the moment when the engine shuts down, or right after the key is turned off. It achieves this with a plunger that uses a spring-loaded mechanism to press right against the primary fuel passage and stop all circulation in it. This means that the same plunger physically shuts down the fuel line and any fuel in it. At the moment when the key is turned on, a special magnetic field is produced by the solenoid, makes the shut off valve’s plunger to be pulled back into the device’s body and opening up the fuel line. In other words, the cycle of use when it comes fuel solenoid shut off valves is completely automated and operates in a stable and independent fashion.

The Purpose of Fuel Solenoid Shut Off Valves:

When this device is used in a truck’s engine, at the moment the ignition key is turned off, it stops any fuel from reaching the engine. This, in turn, stops the fuel from the carburetor from getting to the engine and entering it while it is in its shutdown state. In the opposite case, the unused fuel in an engine can lead to the same engine backfiring, or igniting fuel out of the main engine blocks, which is a very undesirable possibility. Having fuel solenoid shut off valves makes this possibility a lot less likely while it also protects the engine’s state when it comes to its long-term usage.

Having Fuel Solenoid Shut off Valves:

These devices are not only useful but also really affordable. By having them inside of your truck’s engine, its lifespan can be significantly increased and its durability improved as well. Most importantly, because of the construction of these devices, getting fuel solenoid shut off valves means that you will receive standardized devices that were proven to work. With it, you will easily improve the general outlook of your truck.

Author Bio:

Larry Buck is the CEO and the Founder of Foster Truck., a auto/truck parts and accessories selling company. He has 5 years of experience in handling truck fuel solenoid. He shares new, exciting and informative discoveries found by surfing the net.